RESEARCH EXPERTISE THAT CAN HELP YOU GROW

Since its inception in 1989, the Ohio Aerospace Institute (OAI) has provided complex, award-winning on-site research support to the NASA Glenn Research Center (GRC) and the Air Force Research Laboratory (AFRL), while also leading technical projects for numerous other federal laboratories and aerospace entities. OAI is engaged in key areas of aerospace research, development, test and evaluation, public-private partnerships, and policy development

OAI researchers have achieved a track record of significant success and recognition in their fields of endeavor. Representative achievements include numerous patents, published works, leadership roles and key chairmanships within international technical societies and conferences, high profile government honors, and numerous “R&D 100” awards (i.e., recognized as the Oscars for Research and Development).

Contact OAI

Areas of research:

Advanced Aerospace Materials:

High-Performance Solutions for Next-Generation Applications

For decades, OAI has been at the forefront of aerospace material innovation, specializing in the development and application of advanced aerospace materials.

- Light-weight, High-performance Polymers and Structures: Experience in the molecular engineering of advanced polymeric materials and composites includes the synthesis, characterization, process optimization, component design/prototyping, and manufacturing optimization. This approach enables the predictable material behavior in various applications across industries such as aeronautics, space, marine, automotive, medical, and durable goods.

- Ceramics and Metallics: OAI’s pioneering research and development efforts have optimized the performance and properties of ceramics and metallics for diverse applications. This includes novel integration technologies for joining dissimilar materials under various thermo-structural conditions ensuring compatibility and efficient integration.

- Shape Memory Alloys: Experience in the development of stable, high-work-output shape memory alloys that provide design capabilities for adaptive structures and actuators in a range of application temperatures and stress levels that meet the demanding requirements of aerospace and other industries.

Aerospace Systems Sensing, Characterization & Safety Services

The cutting-edge technologies and methodologies developed at OAI enhance the safety and performance of aerospace systems. The experience of our teams span a wide range of areas, including

- NDE and Health Monitoring: Harnessing health monitoring data to ensure the structural integrity and performance of aerospace systems.

- High Temperature Electronics: The development and packaging of high-temperature electronics designed for the harsh environments.

- Laser Diagnostics for Combustion Research: Advanced laser diagnostics techniques that enable the measurement of critical parameters under varying conditions, including subsonic, supersonic, and pressure-controlled cruise conditions.

- Aircraft Icing Research: Computational tools for predicting ice growth, ice protection system behavior, and the effects of ice contamination on aircraft design, analysis, and certification to continuously improve ice accretion and ice protection system prediction methods.

- Ice Adhesion Behavior: Comprehensive approaches that include characterizing ice adhesion behavior, developing innovative test techniques, and employing in-situ monitoring tools to a statistically significant number of specimens under various icing conditions to ensure the reliability and effectiveness of our research.

Computational Modeling:

Advancing Aerospace Propulsion Systems and Environmental Sustainability

OAI, in collaboration with AFRL and GRC, specializes in computational modeling to support the technology development of air and space vehicles, including both airframe and propulsion systems. Expertise spans the development of theoretical and computational models for system components, advancing knowledge and understanding, reducing costs, and minimizing environmental impact. The collaborations also explore the development of models and prediction codes for propulsion system noise and turbulence-chemistry interaction in reacting multi-phase flow simulations.

- Supporting Technology Development for Air/Space Vehicle Propulsion Systems: Through computational modeling to assist the design and analysis process, advanced solutions are provided that optimize the performance and efficiency of air/space vehicle propulsion systems.

- Advancing Knowledge and Understanding: By leveraging computational modeling techniques, fundamental research is conducted in multi-disciplinary physics to explore the intricate relationships between aerodynamics, thermodynamics, and materials science. Uncertainty quantification and sensitivity analysis is performed to assess the impact of uncertainties and optimize system performance.

- Reducing Cost of Access to Space by Improved Performance and Efficiency: Through computational modeling, aerospace propulsion system designs are analyzed and optimized to achieve the highest levels of performance while minimizing costs. These efforts aim to make space more accessible by improving the affordability and reliability of propulsion systems.

- Reducing Environmental Impact: OAI is committed to minimizing the environmental impact of aerospace propulsion systems, specifically in terms of noise and emissions. OAI developed models analyze and reduce propulsion system noise, as well as turbulence-chemistry interactions that contribute to cleaner and more efficient propulsion technologies.

- AFRL OAI On-Site Support: OAI offers on-site support services to AFRL to compliment research talent. OAI expertise in multi-disciplinary physics, uncertainty quantification, sensitivity analysis, and high-speed flows enables us to provide specialized support to researchers and projects, assisting in the design, analysis, and optimization of aerospace systems. Additionally, we optimize software and hardware for high-performance computing, ensuring efficient and accurate simulations.

Mechanical Characterization and Modeling:

Advancing Aerospace Structural Analysis and Durability Estimation

OAI can provide the mechanical characterization and modeling capabilities to enhance the understanding and performance of aerospace structural materials and components.

- Testing Methodologies for High-Temperature Structural Materials: Advanced testing methodologies can be tailored for high-temperature structural materials, sub-elements, and components to ensure the integrity and reliability of aerospace structures operating in extreme environments.

- Thermal, Dynamic, and Stress Analyses of Aerospace Structural Elements: Sophisticated finite element methods perform thermal, dynamic, and stress analyses of aerospace structural elements to optimize the overall performance of aerospace systems.

- Simulation of Lightning Strike Effects on Delamination: Understanding the impact of lightning strikes on aerospace structures is crucial for ensuring safety and reliability. Simulations provide valuable insights into the structural response to develop strategies, designs, and optimal lightning protection systems for aerospace applications.

- Durability Estimation of Aerospace Components: Advanced models and methodologies estimate the durability of aerospace components to accurately predict lifespan and performance. Factors that are considered include creep life, fatigue crack initiation, and fracture mechanics. By integrating durability estimation into the design and maintenance processes, more informed decision-making can be applied to help optimize component life cycles.

Space Science and Exploration Technology:

Advancing Knowledge and Technology for Space Exploration

At OAI, we are dedicated to advancing space exploration knowledge and technology. Through research and development efforts that encompass a wide range of areas, including space propulsion, power, and communications technologies, we push the boundaries of what is possible in space exploration, enabling future missions and expanding our understanding of the universe.

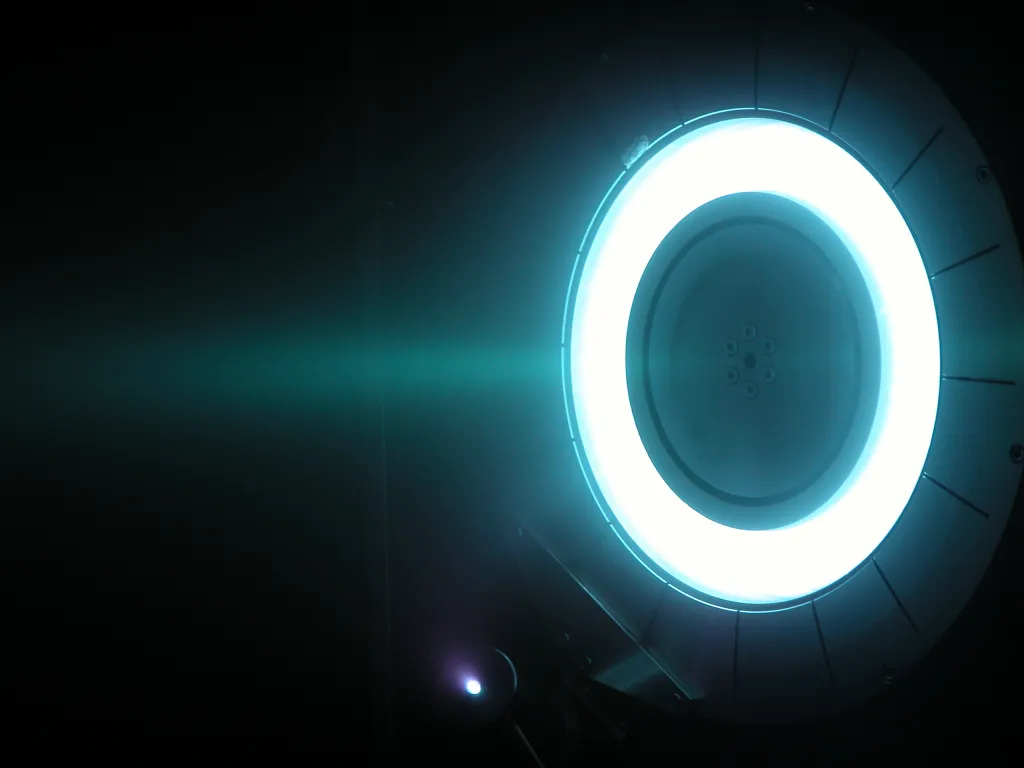

- Development of Space Propulsion, Power, and Communications Technologies: OAI focuses on advancing the capabilities of propulsion systems, including high-power Hall effect thrusters, advanced plasma propulsion, plasma wave acceleration, and advanced solar power technologies. Experience also extends to the development of advanced test sets for space exploration communications, ensuring reliable and efficient communication systems.

- Examination of Space Science and Environmental Interactions: In the field of space science, various aspects of environmental interactions are examined to understand the effects of the space environment on systems and materials. Environmental monitoring instrumentation is developed to gather valuable data, enhancing the understanding of challenges and opportunities presented in space exploration.

- Exploration Technology and Advanced Concepts: As part of our efforts, we investigate concepts and technologies that have the potential to revolutionize space exploration. We actively engage in NIAC (NASA Innovative Advanced Concepts) research, pushing the boundaries of what is possible. Our expertise also extends to the study of space propulsion systems, including solar and nuclear electric propulsion, which hold promise for future deep space missions.

Thermal Management:

Innovative Solutions for Efficient Heat Dissipation

OAI researches thermal management solutions related to heat dissipation for various systems, including aerospace, electronics, directed energy weapons, and energy production. Engineering expertise and the utilization of new advanced materials, such as high conductivity porous graphite foams, offers the potential for operation in high temperature and chemically aggressive environments.

- Utilization of High-Conductivity Porous Graphite Foams: The exceptional properties of high conductivity porous graphite foams provide an ideal combination of lightweight structure and high thermal conductivity, making them suitable for a wide range of applications.

- Replacing Metallic Finned Structures: A key focus area is utilizing high conductivity porous graphite foams as a heat exchanger and replacement for metallic finned structures. By employing these foams, we can enhance heat transfer efficiency, reduce weight, and improve the overall thermal performance of systems.

- Enhancing Thermal Energy Storage Systems: The application of high conductivity porous graphite foams is explored as conductivity enhancers for phase change materials within thermal energy storage systems. By incorporating the foams into these systems, heat transfer is optimized to improve the efficiency of thermal energy storage and release.

- Addressing Production and Durability Challenges: Our projects encompass large-scale production, improving foam durability through coatings, developing joining procedures, and establishing basic design methodologies. Test techniques for producing data are developed to ensure the scalability, reliability, and longevity of thermal management systems utilizing high conductivity porous graphite foams.

Additive Manufacturing of Ceramics:

Pushing the Boundaries of Ceramic Fabrication

OAI has experience in advanced technologies aiming to revolutionize the fabrication process of ceramics for use in harsh environments.

- Additive Manufacturing Techniques for Ceramic Fabrication: OAI is at the forefront of additive manufacturing techniques for ceramics, leveraging cutting-edge technologies to create complex structures with enhanced performance and functionality.

- Laminated Object Manufacturing of Ceramic Matrix Composites: Our team specializes in the research of laminated object manufacturing of ceramic matrix composites (CMCs). This technique allows the fabrication of CMCs with intricate geometries, and tailored properties for enhanced strength, durability, and thermal resistance.

- Study of Processing Constituents and Microstructure Assessment: Research involves an in-depth study of various processing constituents, including SiC powders, infiltrants, and fiber reinforcements to assess their compatibility and performance within the additive manufacturing process.

- Feed Material Development for 3D Printing of SiC-Based Ceramics: OAI focuses on the development and characterization of feed materials specifically designed for 3D printing of silicon carbide (SiC)-based ceramics. By optimizing the material, we can achieve superior printability and control over the final ceramic product's properties and performance.

- Exploring the Potential of 3D Printing Multi-Functional Materials: In addition to traditional ceramics, the possibilities of 3D printed multi-functional materials are explored. By integrating diverse functionalities, new design opportunities and applications are unlocked in various industries.

We are dedicated to pushing the boundaries of aerospace innovation. Partner with us to benefit from our expertise and stay at the forefront of aerospace advancements.